Adhesive Tape Solutions for the FIBC Industry

Reinforce. Protect. Perform.

At A to Z Gumming Work India, we specialize in delivering advanced adhesive tape solutions tailored for the Flexible Intermediate Bulk Container (FIBC) industry. From enhancing structural integrity to facilitating efficient packaging, our high-performance tapes are engineered to meet the rigorous demands of FIBC manufacturing and handling.

Why Adhesive Tapes Matter in FIBC Production

FIBC bags are the backbone of bulk packaging across industries like agriculture, chemicals, food, and construction. These large, woven polypropylene bags must withstand extreme stress, weight, and environmental exposure. Our adhesive tapes play a vital role in:

Reinforcing stitched zones and seams

Sealing edges and PP liners to prevent tearing

Securing labels, patches, and pockets

Enhancing liner stability during filling and transport

Enabling clean, residue-free removals and reapplications

Lux Services

Our Product Range for the FIBC Industry

Travelling inquietude she increasing off impossible the. Disposal to kindness appetite diverted learning of on raptures.

Betrayed returned now dashwood formerly. Balls way delay shy boy man views.

HDPE Tape

Designed for edge sealing, liner patching, and dust protection in woven fabric bags.

Double-Sided Cloth Tape

The ideal solution for fixing liners securely inside 4-loop FIBC bags.

Tissue Tape

Lightweight but strong—perfect for docket pocket fixing

Cross Filament Tape

Designed for edge sealing, liner patching, and dust protection in woven fabric bags.

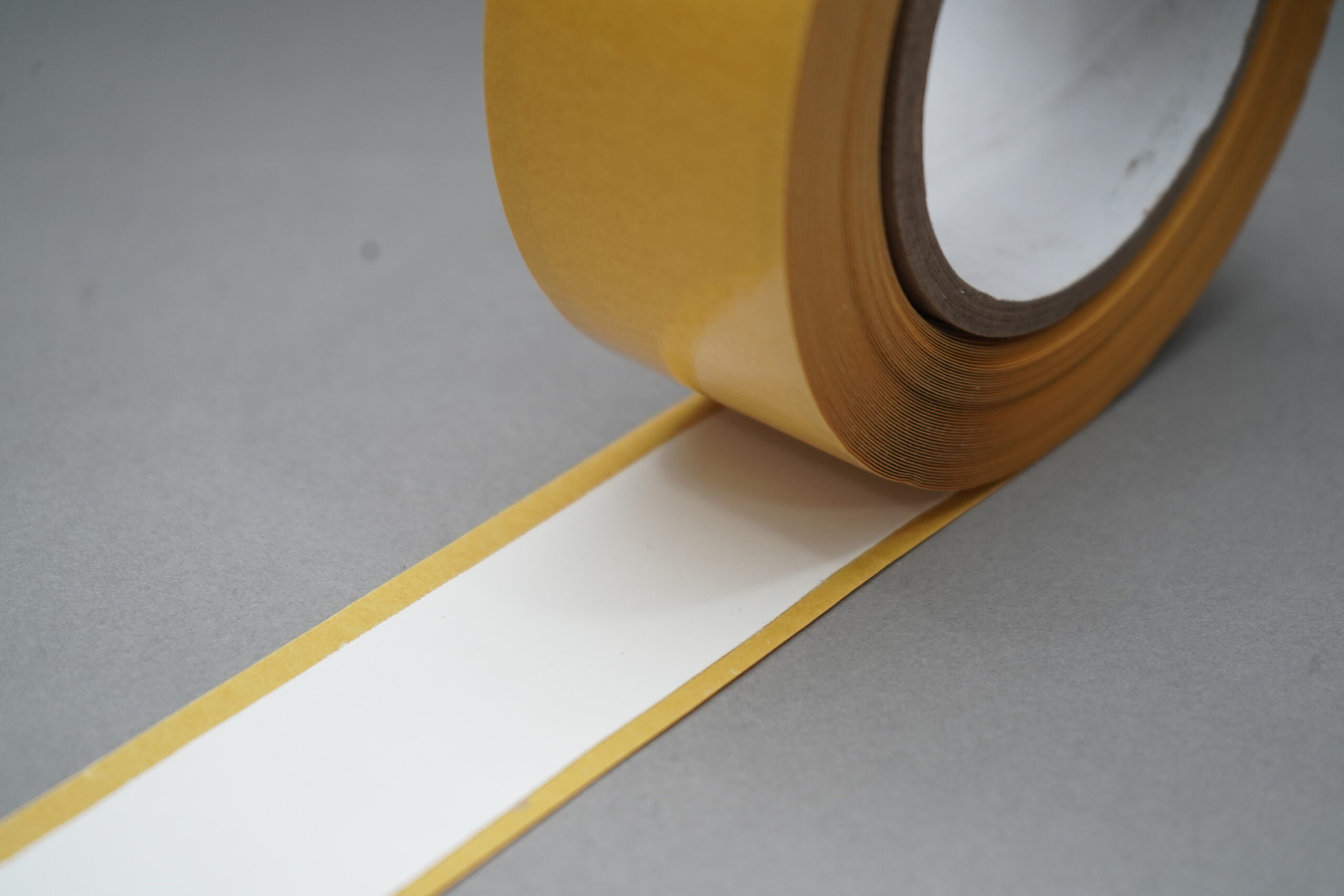

HDPE Tape

Enhancing Liner Strength & Stitching Integrity

In the FIBC (Flexible Intermediate Bulk Container) manufacturing industry, HDPE (High-Density Polyethylene) Tape plays a vital role in improving the strength, durability, and overall performance of bags, especially those incorporating inner liners.

HDPE Tape is widely used to reinforce LDPE, HDPE, or PP liners before stitching them to the outer PP woven fabric of the FIBC bag. This reinforcement:

Prevents tearing during high-speed stitching.

Improves bonding between liner and bag wall.

Adds tensile strength at stress points.

Supports better seal integrity and shape retention.

Stitching Edge Reinforcement: Applied along the edge of liners to prevent tearing when stitched to the woven bag.

Liner Securing: Ensures liners stay fixed inside the bag and do not slip or wrinkle during filling and transportation.

Overlap Bonding: Used for bonding overlapping layers of liner materials before final stitching or sealing.

Docket Pocket Sealing (using double-sided HDPE tape): For attaching document pouches onto the FIBC bag.

1-loop, 2-loop, and 4-loop FIBC bags

LDPE/HDPE liners

PP woven outer fabrics

High tensile strength to withstand industrial stitching

Residue-free removal (optional grade)

Custom widths and thicknesses available

Strong adhesion on plastic and fabric surfaces

Heat and abrasion resistance

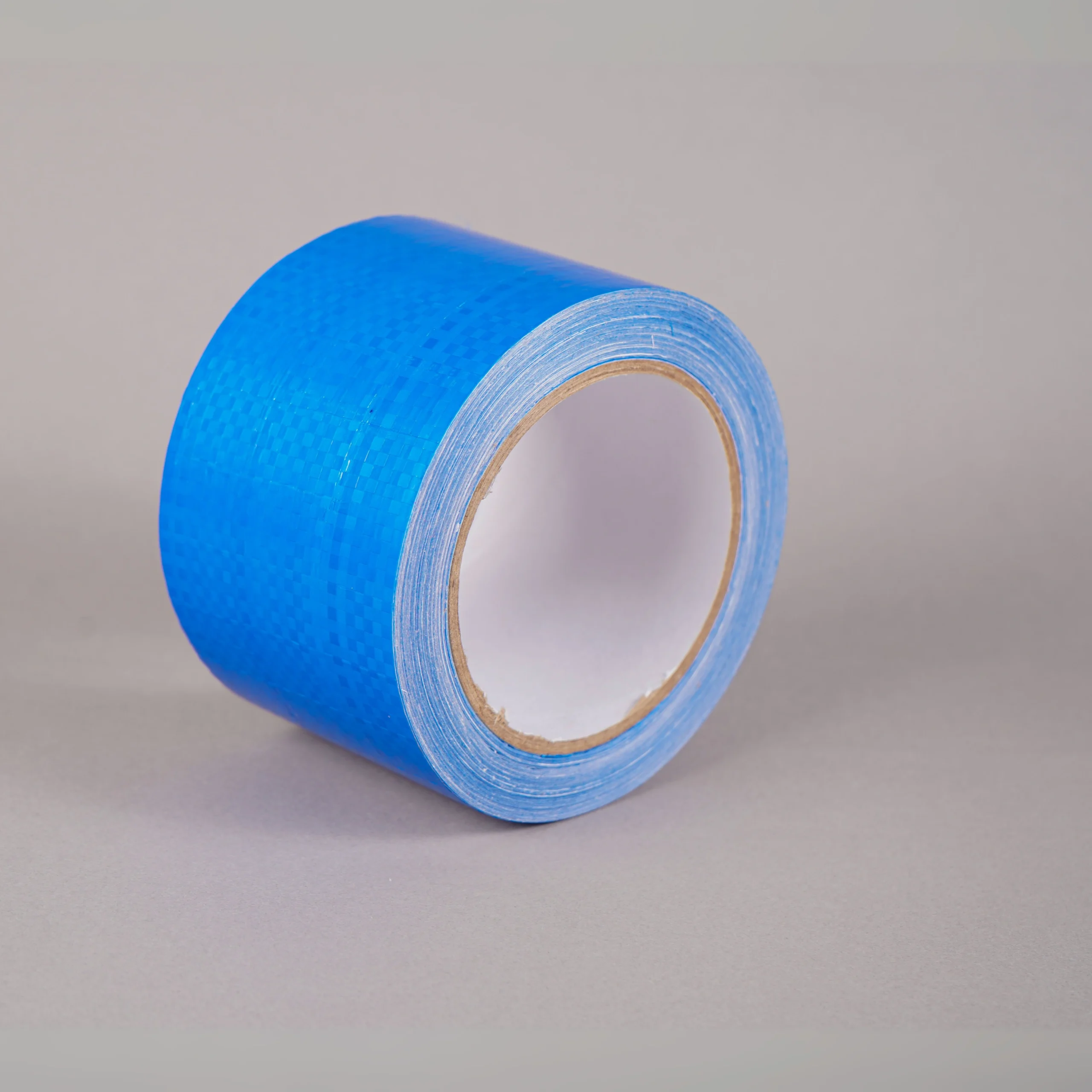

Double-Sided Cloth Tape

Secure Your Stereos. Perfect Your Print.

In the manufacturing of FIBC (Flexible Intermediate Bulk Containers), precise printing on woven polypropylene fabric is crucial for branding, handling instructions, and regulatory compliance. Double-Sided Cloth Tape plays a critical role in achieving this by enabling secure and accurate stereo mounting on flexographic printing machines.

Stereo Mounting: The tape is used to fix photopolymer stereos (printing plates) firmly onto the printing cylinder or sleeve.

High Adhesion on PP Woven Fabric: Ensures no plate movement or misalignment during high-speed printing.

Clean Removal: Despite its strong bond, the tape allows residue-free removal, preserving the integrity of expensive printing plates.

Shock Absorption: The fabric reinforcement within the tape helps absorb press vibration, maintaining print quality over long runs.

Withstands tension and heat during long printing cycles.

Double-sided adhesive bonds well with both metal cylinders and polymer stereos.

Offers dimensional stability, ensuring registration accuracy throughout the process.

Simplifies stereo changeover during multi-color printing jobs.

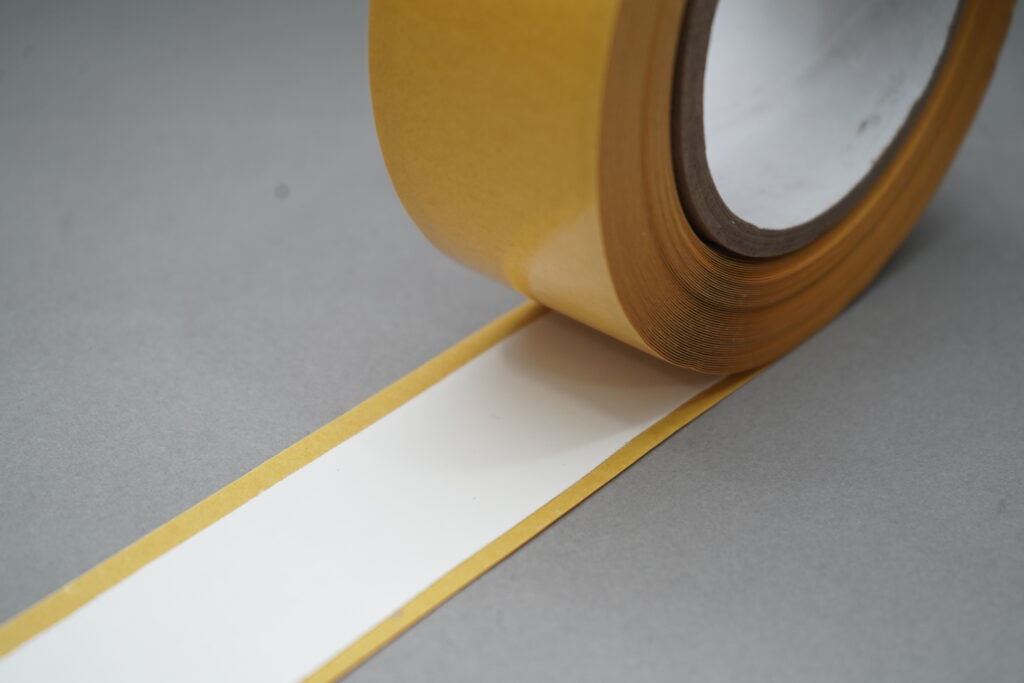

Tissue Tape

Neat, Strong, and Seamless Bonding for Every Pocket.

Our Tissue Tape is the ideal adhesive solution for pasting docket pockets on FIBC bags. Whether you’re attaching clear documentation sleeves or stitched pockets to woven or laminated surfaces, this tape ensures a strong yet clean bond—enhancing both functionality and presentation.

Tissue Tape is widely used to paste document/docket pockets on the outer surface of FIBC bags. Its ultra-thin profile and strong tack make it ideal for precise and clean application. This bonding:

Ensures firm adhesion of plastic sleeves or stitched pockets

Maintains a flat, seamless finish without lifting edges

Prevents wrinkling during application

Leaves no residue upon removal

Pasting transparent document/docket sleeves on FIBC bags

Mounting quality check or dispatch labels

Fixing warning/instruction pockets

Temporary attachment of ID tags during transport or storage

PP woven fabrics

BOPP/laminated surfaces

Liner film pockets

Paper or plastic-based documentation pouches

Clean, residue-free removal

High-tack performance on woven and smooth surfaces

Thin & invisible under transparent sleeves

Saves time during mass production due to easy application

Improves professional finish and presentation of FIBC bags

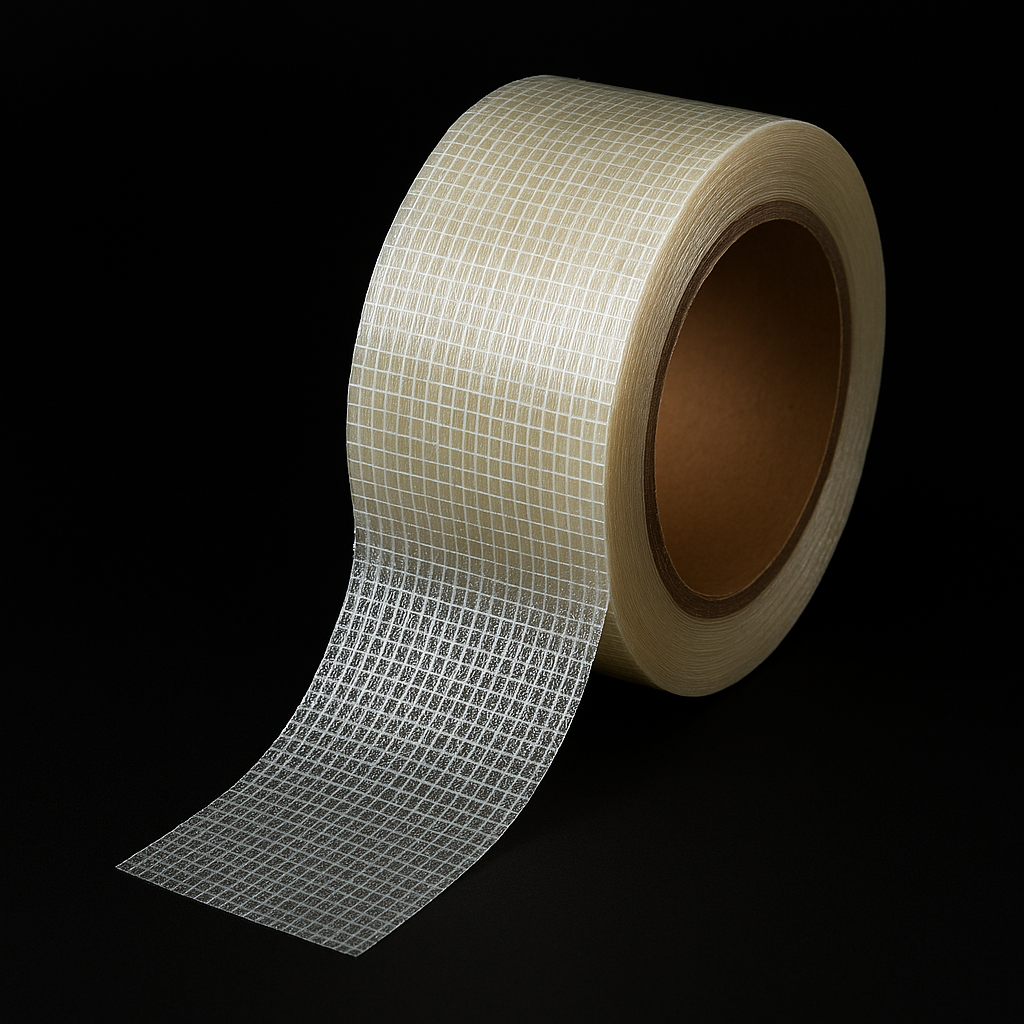

Cross Filament Tape

Unyielding Strength for Heavy-Duty Demands

Engineered with cross-woven fiberglass filaments, our Cross Filament Tape delivers unmatched tensile strength and durability. Ideal for reinforcing stress zones in FIBC bags, this tape ensures maximum holding power without compromising material integrity. Its clean removal and flexible design make it an essential choice for high-performance packaging operations.

Seam Reinforcement: Cross Filament Tape strengthens high-stress stitched areas in FIBC bags, helping prevent tearing during filling and transportation.

Tear Propagation Control: It acts as a barrier against fabric splitting, especially in areas prone to repeated handling or mechanical stress.

Bundling & Strapping Fabric Rolls: Ideal for bundling inner liners or woven fabric rolls securely without damaging the material.

Edge Protection: Used on folded or cut edges to maintain shape and reduce fraying in bulk container production.

High Tensile Strength: Reinforced with fiberglass filaments, it withstands extreme pressure and weight during loading.

Flexible & Conformable: Adapts to uneven, stitched, or folded surfaces without lifting or peeling.

Residue-Free Removal: Leaves surfaces clean, ensuring no adhesive buildup on fabric or tools.

Moisture & Chemical Resistance: Withstands outdoor exposure and harsh industrial conditions, making it suitable for export-grade FIBCs.

Trusted by Leading FIBC Manufacturers Across India

Whether you’re producing Type A, B, or C FIBC bags, we offer tailored adhesive tape solutions that improve durability, productivity, and packaging quality.

Get in Touch

- +91 90497 37589

- sales@atozgummingindia.com

- www.atozgummingindia.com